Research Facilities

Materials Under Extreme Loading Laboratory (MATEX)

The MATEX testing facility at LSU (Materials under Extreme Loadings) conducts impact

damage in materials and structures using both the Split Hopkinson Bar and the high velocity Impact Tester. The Split Hopkinson Pressure Bar of the Impact Testing Facility at LSU (MATEX) is

used for evaluating the dynamic behavior of the architected metamaterials under high-strain-rate

loadings. This facility helps researchers to characterize the material behavior of

materials when subjected to impact loadings. The characterization focuses on the microstructural effects of materials and considering

size effects on the macroscopic behavior of metals, polymers and rocks. This leads

to better constitutive relations for the solution of physical problems due to impact

loads. The MATEX laboratory houses extensive testing facilities in impact and damage

for testing of metals and structures using the Hopkinson Bar equipment as well as

the Impact Tester.

The MATEX testing facility at LSU (Materials under Extreme Loadings) conducts impact

damage in materials and structures using both the Split Hopkinson Bar and the high velocity Impact Tester. The Split Hopkinson Pressure Bar of the Impact Testing Facility at LSU (MATEX) is

used for evaluating the dynamic behavior of the architected metamaterials under high-strain-rate

loadings. This facility helps researchers to characterize the material behavior of

materials when subjected to impact loadings. The characterization focuses on the microstructural effects of materials and considering

size effects on the macroscopic behavior of metals, polymers and rocks. This leads

to better constitutive relations for the solution of physical problems due to impact

loads. The MATEX laboratory houses extensive testing facilities in impact and damage

for testing of metals and structures using the Hopkinson Bar equipment as well as

the Impact Tester.

Advanced Computational Solid Mechanics Laboratory (CSM)

Dr. George Z. Voyiadjis, Boyd Professor, is the director of the Advanced Computational Solid Mechanics Laboratory (CSM). The CSM lab promotes research in materials science at LSU and in conjunction with other research facilities and teams around the world. By specializing in numerical analysis and experimentation at the nanoscale, CSM Lab pioneers the advancement of knowledge in this emerging area of science. Engineers, scientists, and technicians design new products for many reasons: to increase productivity and efficiency in the industrial process, to reduce the cost of manufacturing, to replace existing products that are aging, and to add new features that will benefit people's lives. Throughout the design process, the selection and preparation of proper materials are crucial to achieving the desired result. As researchers understand more of how and why materials behave under real-world conditions, they can use that knowledge to create materials that are stronger, lighter, tougher, safer, etc. than those that are commercially available today. Building on the discoveries of past research efforts, this laboratory uses information from experiments and numerical simulations with materials. This laboratory, in conjunction with the Center for Computing and Technology, CCT, uses advanced cyberinfrastructure –high-speed networks, high-performance computing, advanced data storage and analysis, and hardware and software development-to properly characterize material behaviors.

The research objectives of this laboratory are to (1) design ultralightweight high-strength mechanical metamaterials, (2) formulate a multiscale computational model combining hierarchies with material size effects, and (3) conduct laboratory experiments with 3D printed cellular metamaterials for multifunctional aerospace applications. In the context of advanced materials, the next generation of architected cellular materials has the potential to excel in functional and structural limitations. Architected cellular materials with optimized unit cell topologies have enormous potential to achieve combinations of properties unavailable in any existing monolithic material. Advances in additive manufacturing technologies have enabled the fabrication of macro-scale architected materials with key dimensional features at the micro and nanoscale levels, resulting in dramatic improvements in their mechanical and multifunctional properties. Compared with conventional composites, architected cellular materials can further lower weight, thereby reducing both energy consumption and pollution, still major challenges to address, especially for aerospace and automotive industries. This work is an important step toward the scalable fabrication of multifunctional ultralightweight architected cellular metamaterials that are currently lacking.

Driving Simulator Lab

The driving simulator lab hosts the LSU Driving Simulator, a full-sized passenger

car (Ford Fusion) combined with a series of cameras, projectors and screens to provide

a high fidelity virtual environment that offers a high degree of driving realism.

It provides a one degree of freedom motion simulation to make a driver experience

similar driving efforts as in an instrumented vehicle. Its open architecture software

tools allows for data collection during simulation experiments, and creation of new

networks and virtually an infinite number of simulation scenarios. Vehicle simulation

makes it possible for inexpensive alternatives and sometimes impossible (unethical

or safety implications) field tests to be undertaken in the lab. Research conducted

in the lab include safety in work zones, examining driving behavior of distracted

drivers, testing driver reactions and performance under varying categories of hurricane

winds, and development of a connected-vehicles simulation test-bed. The lab is also

capable of examining the effects of different levels of task complexity on visual

fixation strategies and visual stimulus recognition, determining the effect of road

signage, road type and other factors on driver performance, testing driver reactions

and performance with new in-vehicle technology devices, and determining effects of

fatigue and other distraction levels on driving performance. Such experiments advance

the state of the art in driving simulation, and do result in valuable findings that

may save lives.

The driving simulator lab hosts the LSU Driving Simulator, a full-sized passenger

car (Ford Fusion) combined with a series of cameras, projectors and screens to provide

a high fidelity virtual environment that offers a high degree of driving realism.

It provides a one degree of freedom motion simulation to make a driver experience

similar driving efforts as in an instrumented vehicle. Its open architecture software

tools allows for data collection during simulation experiments, and creation of new

networks and virtually an infinite number of simulation scenarios. Vehicle simulation

makes it possible for inexpensive alternatives and sometimes impossible (unethical

or safety implications) field tests to be undertaken in the lab. Research conducted

in the lab include safety in work zones, examining driving behavior of distracted

drivers, testing driver reactions and performance under varying categories of hurricane

winds, and development of a connected-vehicles simulation test-bed. The lab is also

capable of examining the effects of different levels of task complexity on visual

fixation strategies and visual stimulus recognition, determining the effect of road

signage, road type and other factors on driver performance, testing driver reactions

and performance with new in-vehicle technology devices, and determining effects of

fatigue and other distraction levels on driving performance. Such experiments advance

the state of the art in driving simulation, and do result in valuable findings that

may save lives.

Structural Systems Testing Laboratory

Testing of structural components and subsystems is conducted using a 550-kip MTS tall load frame equipped with an MTS Flextest SE controller and National Instruments cDAQ-9178 data acquisition system with strain, thermocouple, voltage, and accelerometer modules. Measurement capabilities include strain gages and Linear Variable Differential Transformers (LVDTs). Hydraulic systems in the lab are powered with state-of-the-art pumps (MTS SilentFlo series). A variety of loading tips, spreader beams and custom fixtures are available.

In the near future (2014), the lab will be equipped with a strong reaction floor to allow testing components with a wider footprint. It will also allow setting multiple tests simultaneously.

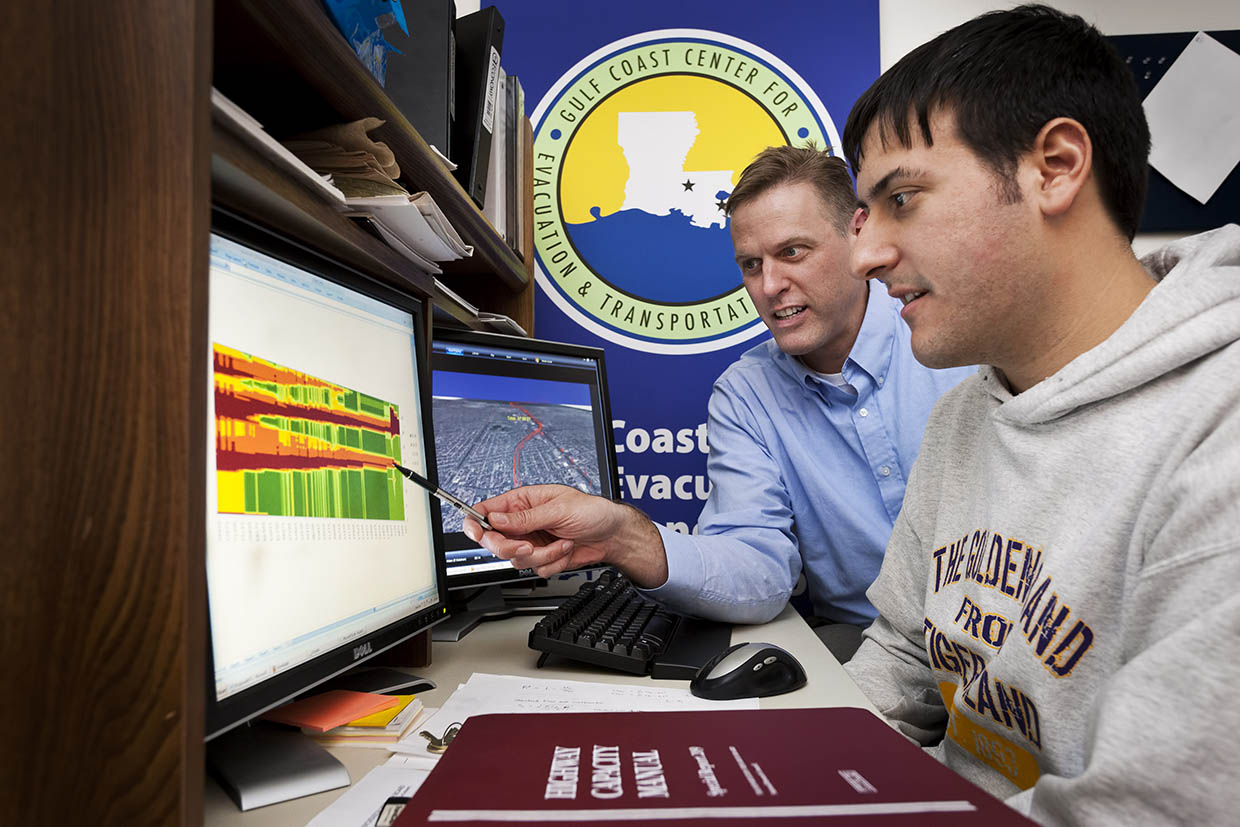

Gulf Coast Center for Evacuation & Transportation Resiliency

The Gulf Coast Research Center for Evacuation and Transportation Resiliency, under the direction of Dr. Brian Wolshon, is a collaborative effort between the Louisiana State University's Department of Civil and Environmental Engineering and the University of New Orleans' Department of Planning and Urban Studies. The theme of the LSU-UNO Center is focused on Evacuation and Transportation Resiliency in an effort to address the multitude of issues that impact transportation processes under emergency conditions such as evacuation and other types of major events. This area of research also addresses the need to develop and maintain the ability of transportation systems to economically, efficiently, and safely respond to the changing demands that may be placed upon them.

For more information about the Gulf Coast Center for Evacuation & Transportation Resiliency, visit them online at http://www.evaccenter.lsu.edu/

Center for River Studies

The Center for River Studies is a collaborative partnership between the Coastal Protection

and Restoration Authority and LSU. The primary focus of the Center is to operate one

of the world's largest physical models of the Mississippi River to produce qualitative land-building

results associated with sediment diversion in the lower river. Based on exact parameters

of the river's physical an dynamic properties, the model flows sediment and water,

covering a 14.000-square-mile section of southeast Louisiana. The lower Mississippi

River Physical Model, a 90 x 120 foot movable bed, is one of the largest of its kind

in the world and the facility was specifically designed for the model. The foundation,

overhead gantry crane, walk-bridge, interior drainage, electrical system, and data

infrastructure were all designed to facilitate the model and exhibit. One hour of

model testing time is equivalent to one year of natural river time, therefore 100-year

project scenarios take approximately 100 hours on the model. Additionally, 20 high-resolution

digital projectors are mounted above the model and are able to merge together and

project aerial photographs, project features, diversion outputs, and other simulations/animations.

world's largest physical models of the Mississippi River to produce qualitative land-building

results associated with sediment diversion in the lower river. Based on exact parameters

of the river's physical an dynamic properties, the model flows sediment and water,

covering a 14.000-square-mile section of southeast Louisiana. The lower Mississippi

River Physical Model, a 90 x 120 foot movable bed, is one of the largest of its kind

in the world and the facility was specifically designed for the model. The foundation,

overhead gantry crane, walk-bridge, interior drainage, electrical system, and data

infrastructure were all designed to facilitate the model and exhibit. One hour of

model testing time is equivalent to one year of natural river time, therefore 100-year

project scenarios take approximately 100 hours on the model. Additionally, 20 high-resolution

digital projectors are mounted above the model and are able to merge together and

project aerial photographs, project features, diversion outputs, and other simulations/animations.

L.H. Bossier Asphalt Laboratory

The L.H. Bossier Asphalt Laboratory is used for undergraduate and graduate classroom

demonstrations and laboratory classes. When not occupied for classes, the lab is used

for student and faculty research involving the composition and qualities of different

types of asphalt, and ways to improve its installation, function and longevity.

The L.H. Bossier Asphalt Laboratory is used for undergraduate and graduate classroom

demonstrations and laboratory classes. When not occupied for classes, the lab is used

for student and faculty research involving the composition and qualities of different

types of asphalt, and ways to improve its installation, function and longevity.

ETEC Hydraulics and Water Distribution Laboratory

The ETEC Hydraulics and Water Distribution Lab provides Civil and Environmental Engineering undergraduate students with an experimental and modeling facility where they can get hands-on experience in the real-time monitoring, control, and modeling of hydraulic systems. The lab, sponsored by Environmental Technical Sales, Inc., currently consists of a series of pipes in various diameters, valves, switches, flow meters and pressure gages that are all connected to two reservoirs for water distribution control problems. This pipe loop system can be configured to operate as independent individual loops, collectively as one unit, or in various configurations. Several PC-based computers are set up, some for running water distribution control and monitoring software and the others running monitoring software and hydraulic modeling software. The real-time monitoring and optimization software equips students with the ability to provide constant flow control according to changing demands, while monitoring main water lines, reservoir levels, water quality, etc. The software also enables continuous monitoring of water quantities and pressures. Extensive renovations are underway that include additional computer workstations to serve as a means to control, monitor, and model tracer movement through the system. Also, a connection system will be put into place to open the channel flume where small turbines will be located. The operation and monitoring of these turbines will also be done at these additional workstations.

Geotechnical Engineering Laboratory

The Geotechnical Engineering Laboratory is equipped with testing equipment for (a) geophysical monitoring: a signal generator (33509B,Agilent) for S-wave excitation, a high-voltage pulser (5077PR,Panametric) for P-wave excitation, a signal amplifier (3944, Krohn-Hite), and a digital oscilloscope (DSOX2024, Agilent) for acquiring transmitted waves, (b) high-pressure testing system: a high-pressure syringe pump which can control the pressure up to 5000 psi and the flow rate as slow as 0.001 mL/min, temperature controller, and (c) standard and specialized soil testing: the geotechnical engineering laboratories are equipped to conduct all the standard physical and engineering properties tests on soils including gradation, specific gravity, Atterberg limits, permeability, shear strength, compaction, and consolidation. One unique feature of the geotechnical laboratories is that possess two true cubical triaxial testing devices (for low and high pressure testing regiomes). These devices are fully equipped with data acquisition systems.

Louisiana Transportation Research Center (LTRC)

Since its creation by the legislature in 1986, the Louisiana Transportation Research

Center (LTRC) has grown to national prominence through its efforts to improve transportation

systems in Louisiana. The center conducts short-term and long-term research and provides

technology assistance, engineering training and continuing education, technology transfer,

and problem-solving services to DOTD and others in the transportation community.

The center, sponsored jointly by Louisiana State University and the Louisiana Department

of Transportation and Development, is largely supported by funding authorized by the

Federal Highway Administration. LTRC's goal is to merge the resources of state government

and universities to identify, develop, and implement new technology to improve the

state's transportation system. LTRC combines the efforts of DOTD and the state's universities

to find innovative solutions to Louisiana's transportation problems.

For more information about the Louisiana Transportation Research Center, visit them online at http://www.ltrc.lsu.edu.